1. Application of lithium batteries in ship power Background: Traditional diesel-powered ships have problems such as high cost, loud noise, and heavy pollution. Lithium-Battery electric ships have become the only new energy solution that can achieve zero emissions and initial scale.

Applicable scenarios: Pure electric vessels: Fixed short-route vessels (ferries, tugboats, cruise ships, etc.) rely on the economic, flexibility, and low-vibration advantages of electric propulsion. Hybrid ships: For long-haul routes, diesel-electric hybrids balance endurance and emissions reduction. Technological breakthroughs: Electric propulsion faces load disturbance problems (due to the volatile marine environment and complex operating conditions of engineering vessels). Energy Storage technology (such as lithium batteries) is used to smooth out the impact and improve system stability. Lithium batteries play the role of energy supply/storage in hybrid power, achieving peak shaving and valley filling, compensating for generator defects, and providing direct power supply (zero emissions).

2. Application of lithium batteries in ship energy storage Function: Solve the problem of inefficient fuel combustion and increased pollution caused by load fluctuations in ship power grids.

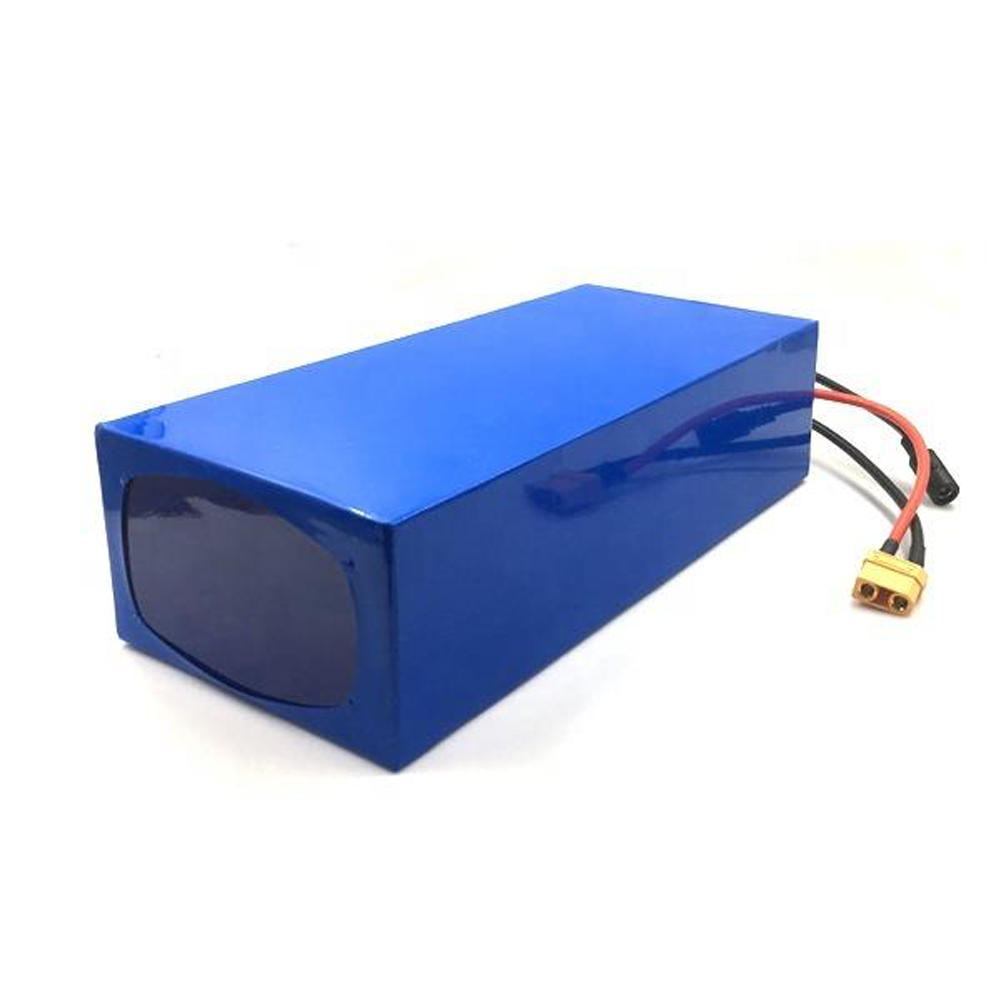

Energy storage method comparison: Applicable solutions for ships: Battery Energy storage (lead-acid/lithium battery), supercapacitor, and flywheel energy storage. Lithium battery advantages: high specific energy (lithium iron phosphate reaches 190Wh/kg) and long cycle life (over 2,000 cycles). Disadvantages: heat dissipation and safety need to be optimized. Mainstream choices: Lithium iron phosphate batteries have become the first choice for domestic ship applications due to their high safety (temperature resistance of 350°C), low cost, environmental protection and lack of heavy metals; ternary lithium batteries have not yet been popularized due to limited safety investment.

3. Policies and Regulations National Policy: 2018-2020: The Ministry of Transport and other departments successively issued documents to promote clean energy ships (including lithium batteries), requiring the elimination of old diesel ships and the development of new energy technologies. Local incentives: Shenzhen, Guangzhou and other places have introduced subsidies and fuel-powered vessel bans and restrictions. Standard missing: International: The SOLAS Convention does not cover pure battery power, and classification society regulations are fragmented. Domestic: The "Guidelines for Inspection of Pure Battery-Powered Ships" and technical requirements for batteries for inland vessels were issued in 2019, but standards for coastal vessels still need to be improved.

4. Application Status and Problems Global scale: In 2019, there were 155 electric ships (75 in operation), with battery capacities ranging from 1,000 to 4,000 kWh. Over 20 electric ships were operating on China's inland waterways, with a maximum capacity of 3,000 kWh (all using lithium iron phosphate). Core Question: Lack of planning: There is a lack of unified national deployment of technology paths, subsidies (system costs are 2.2-2.5 times that of traditional ones), and battery lifecycle management (ship life is 20 years vs. battery life of 8 years). Insufficient regulations: The standards for marine lithium batteries are based on automotive standards (IEC/national standards), but do not take into account the large capacity of ships (several dozen times that of vehicles) and the harsh environment requirements. Technical bottlenecks: battery safety risks (fire/failure), ship design not adapted to power characteristics, and weak supporting industries (few domestic companies certified for marine batteries). Ship type restrictions: Domestic ship battery capacity <5000KWh, only applicable to short-distance passenger ships, ferries, and cargo ships (tonnage <2000 tons).

5. Core advantages of lithium iron phosphate batteries Safety: Olivine has a stable structure and its high temperature tolerance (350℃-500℃) is better than other lithium batteries. Lifespan and economy: Cycle life of 2000+ times (lead-acid batteries only 300 times), mass production energy density reaches 190Wh/kg and costs continue to decline. Environmental protection: No heavy metal pollution, compliant with EU RoHS directive.

6. Application Scenarios and Prospects Current vessel types: tourist boats, ferries, inland cargo ships, and harbor tugboats (under 2,000 tons). Development direction: Priority will be given to promoting closed waters such as inland rivers and lakes, relying on policy promotion and breakthroughs in energy storage technology.

7. PTP lithium battery company introduction:

Dongguan Pack Team Power Technology Co., Limited. is a high-tech enterprise integrating the research and development, production and sales of lithium ion batteries. we have factories in Dongguan with an annual output of 2.5Gwh battery packs and 5Gwh battery packs and energy storage products. Most of our management have more than 20 years of experience from leading companies in the field of lithium batteries and energy storage, such as CATL, CATL Times and Swart. Haiping Hu, Chairman of the company, is a leader in the field of energy storage materials and finished products with 25 years of experience. PTP's mission is to contribute our expertise to create a sustainable future for the world.

Related News

- Global First Sodium-Ion Battery-Powered Passenger Car Set for Mass Production!

- 48V80Ah Battery Pack | Reliable Solutions for Energy Storage, UPS, and AGV

- Expanding Applications and Market Growth of Lithium Batteries

- Advanced LiFePO4 and Lithium-Ion Batteries,Sustainable Energy Storage

- Comparing Lithium-Ion and Sodium-Ion Batteries

- High-Performance 12V Battery Packs | Reliable Energy Solutions

- Home Energy Storage Systems in 2025 Trends, Benefits, and Market Outlook

- The Five Fundamental Design Principles for Energy Storage Cabinets

- Safety Guide for Homes with Solar Power Generation, BESS and EVs

- How Long Do Electric Vehicle Batteries Last? Comparing Lead-Acid & Lithium